E Fetileng Molds Ho etsa le Mahala lihlahisoa moralo

Likarolo tsa ho Enta ka Plastiki - Moralo le Tlhahiso bakeng sa Litlhoko tsa Hao

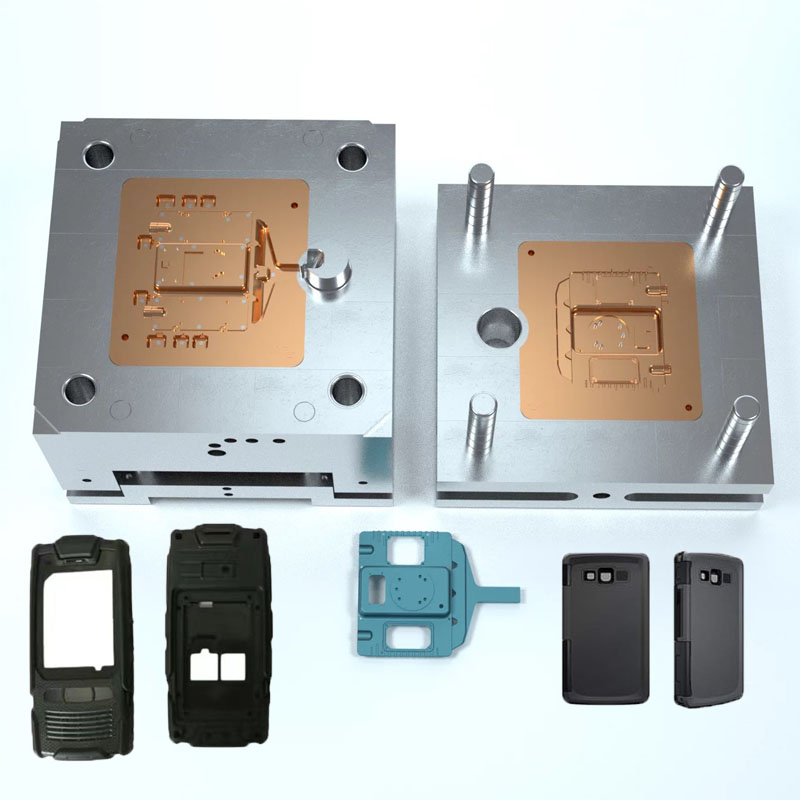

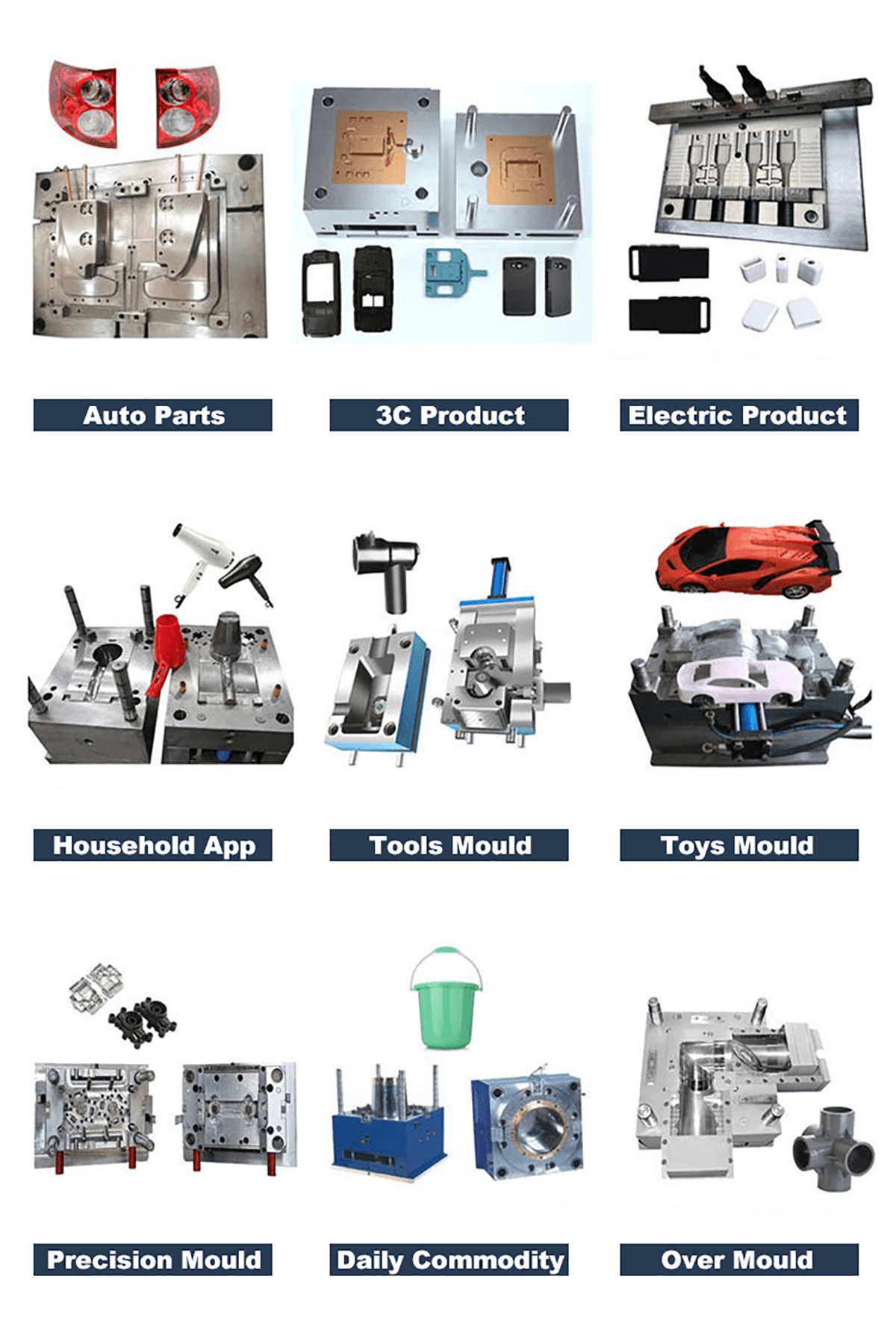

Khamphani ea rona, re motlotlo ka ho fana ka litšebeletso tsa boemo ba pele lefapheng la tlhahiso ea likarolo tse entsoeng ka ente ea polasetiki.Ka liforomo tsa rona tse entsoeng ka mokhoa o nepahetseng haholo le theknoloji ea ho bopa ente, re khona ho hlahisa likarolo tsa polasetiki habonolo.Sehlopha sa rona sa baenjiniere ba nang le litsebo tse phahameng se ikemiselitse ho etsa ka nako e loketseng likarolo tse entsoeng ka ente ea polasetiki.Ka boiphihlelo bo fetileng, re atlehile ho etsa hlobo bakeng sa liindasteri tse fapaneng, ho kenyelletsa lisebelisoa tsa lapeng, lintho tsa ho bapala, lihlahisoa tsa elektroniki tsa 3C, likarolo tsa koloi le litlhoko tsa letsatsi le letsatsi, joalo-joalo Ho feta moo, matla a rona a tlhahiso ea khoeli le khoeli a re nolofalletsa ho hlahisa lihlopha tse 200 tsa liforomo tse nepahetseng le ho kenya 200,000. -500,000 likotoana tsa likarolo tsa polasetiki.

Ha ho etsoa likarolo tse entsoeng ka ente, ho nepahala le boleng ke tsa bohlokoa ka ho fetisisa.Ho utloisisa bohlokoa ba lintlha tsena, k'hamphani ea ronae tsetela ho theknoloji ea morao-rao le mechiniho etsa bonnete ba hore re fana ka lihlahisoa tse fihlelang litebello tsa bareki ba rona.

E 'ngoe ea matla a rona a holim'a liforomo tse nepahetseng haholo tseo re li etsang.Mefuta ena e phetha karolo ea bohlokoa ts'ebetsong ea ente ha e ntse e khetholla sebopeho sa ho qetela le boleng ba karolo.Baenjineri ba rona ba na le tsebo ea ho etsa hlobo, ba etsa bonnete ba hore hlobo e 'ngoe le e 'ngoe e entsoe ka hloko ebile e entsoe ka nepo ho fihlela litlhoko tsa bareki ba rona.Ebang ke moralo o rarahaneng kapa o bonolo, sehlopha sa rona se na le boiphihlelo ba ho etsa hlobo e hlahisang likarolo tsa polasetiki tsa boleng bo holimo.

Ntle le tsebo ea rona ea ho etsa hlobo, re tsetetse mochining oa morao-rao oa ho bopa ente.Mechine ena e na le lisebelisoa tse tsoetseng pele tse re lumellang ho hlahisa likarolo tsa polasetiki ka mokhoa o atlehileng le o nepahetseng.Ka thuso ea mechine ena, re khona ho finyella liphello tse tsitsitseng, ho netefatsa hore karolo e 'ngoe le e 'ngoe e finyella litekanyetso tse hlokahalang.Ho feta moo, ts'ebetso ea rona ea ho bopa ente e iketsetsa haholo, e fokotsa kotsi ea liphoso le ho fokotsa linako tsa tlhahiso.

Khamphani ea rona e fana ka liindasteri tse fapaneng, ho kenyelletsa lisebelisoa tsa lapeng, lintho tsa ho bapala, lihlahisoa tsa elektroniki tsa 3C, likarolo tsa koloi le litlhoko tsa letsatsi le letsatsi.Phihlelo ea ronaliindastering tsena li re fa kutloisiso e tebileng ea litlhoko tsa bona tse khethehileng.Tsebo ena e re thusa ho fana ka litharollo tsa moetlo tse fihlelang litlhoko tse ikhethang tsa bareki ba rona.Ebang ke tlhahiso e nyane kapa morero o moholo, re ikemiselitse ho fana ka likarolo tse entsoeng ka ente ea boleng bo holimo tse fetang tebello.

Ha re sebetsa le bareki, re etelletsa pele puisano e hlakileng le kutloisiso.Ho tloha lipuisanong tsa pele ho isa ho phano ea ho qetela, re sebetsa haufi-ufi le bareki ba rona ho netefatsa hore litlhoko tsa bona lia fihlelleha.Sehlopha sa rona sa lienjiniere le litsebi li teng ho rarolla mathata leha e le afe kapa lipotso tse ka hlahang.Re lumela hore puisano e sebetsang ke senotlolo sa tšebelisano e atlehileng mme re ikitlaelletsa ho theha likamano tse tšoarellang le bareki ba rona.

Mabapi le matla a tlhahiso, re khona ho sebetsana le merero e meholo.Ka matla a tlhahiso ea lihlopha tse 200 tsa liforomo tse nepahetseng ka khoeli le bokhoni ba ho kenya hlobo ea likarolo tsa polasetiki tse 200,000-500,000, re ka kopana le linako tse thata tsa ho fana ka thepa ntle le ho senya boleng.Mekhoa ea rona ea tlhahiso e sebetsang hantle le phallo e hlophisitsoeng ea mosebetsi e re lumella ho ntlafatsa tlhahiso le ho netefatsa hore bareki ba rona ba fumana litaelo tsa bona ka nako.

Qetellong, k'hamphani ea rona ke morekisi ea tšepahalang oa likarolo tse entsoeng ka ente ea boleng bo holimo.Ka liforomo tsa rona tse entsoeng ka mokhoa o nepahetseng haholo le theknoloji ea ho bopa ente, re khona ho hlahisa likarolo tsa polasetiki habonolo.Boiphihlelo ba rona, botsebi le boitlamo ba rona ba boleng bo re etsa khetho ea pele liindastering tse kang lisebelisoa tsa lapeng, lintho tsa ho bapala, lisebelisoa tsa elektroniki tsa 3C, likarolo tsa koloi le litlhoko tsa letsatsi le letsatsi.Kahoo hore na o hloka tlhahiso e nyane kapa projeke e kholo, sehlopha sa rona se ikemiselitse ho fana ka liphetho tse hlahelletseng.

Lintlha tsa Sehlahisoa

| Sebaka sa Tšimoloho | China |

| Lebitso la Brand | HSLD/ E etselitsoeng motho |

| Mokhoa oa ho Shaping | Fans Plastic Ente Mold |

| Thepa | CNC, Mochini o Sehang oa EDM, Mechini ea polasetiki, joalo-joalo |

| Boitsebiso ba Sehlahisoa | Tšepe: AP20/718/738/NAK80/S136 Plastiki: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Bophelo ba Hlobo | 300000 ~ 500000 Shots |

| Semathi | Semathi se Chesang kapa Semathi se Cold |

| Mofuta oa heke | Ntlheng / Pin point/Sub/Side Heke |

| Phekolo ea bokaholimo | Matte, e bentšitsoeng, seipone se bentšitsoeng, sebopeho, pente, joalo-joalo. |

| Mold Cavity | Mokoti o le Mong kapa o Angata |

| Mamello | 0.01mm -0.02mm |

| Mochini oa Ente | 80T-1200T |

| Mamello | ± 0.01mm |

| Mohlala oa mahala | fumaneha |

| Molemo | tharollo e le 'ngoe ea ho emisa / moralo oa mahala |

| Sebaka sa kopo | Lihlahisoa tsa elektroniki, lihlahisoa tsa botle, lihlahisoa tsa bongaka, Lihlahisoa tse sebelisoang lapeng, Lihlahisoa tsa Auto, jj |

Ho Bopa ka Ente ea Plastiki: Phetoho ea Lipapali Makaleng a B-End

Selelekela

Ho bopa ente ea polasetiki e hlile e fetotse mekhoa ea tlhahiso ho liindasteri tse fapaneng tsa B-End, ho bula menyetla e sa feleng ea boqapi le tsoelo-pele.Sengoliloeng sena se hlasimollang, re tla shebana le lefats'e le leholo le le monate la ts'ebeliso ea ente ea polasetiki molemong oa ho etsa likoloi, lisebelisoa tsa elektroniki tsa bareki, indasteri ea ho paka le tlhokomelo ea bophelo bo botle.Ka ho bonts'a mehlala ea 'nete le ho e tšehetsa ka lintlha tse khothatsang, re tla taka setšoantšo se hlakileng sa kamoo mokhoa ona o feto-fetohang le ho ntlafatsa makala ana ka mokhoa o makatsang.

Plastiki Ente Molding ka Automotive Manufacturing

Indasteri ea likoloi e na le botumo ba ho nchafatsa le ho ntlafatsa kamehla.Ho tloha ho lienjineri tsa boemo bo holimo ho isa lits'ebetsong tse tsoetseng pele tsa polokeho, bahlahisi ba lula ba batla litsela tsa ho ntlafatsa ts'ebetso ea koloi le botle bo botle.Mokhoa oa phetoho o fetolang papali ea ho etsa likoloi ke ho etsa ente ea polasetiki.

Ka ho sebelisa ts'ebetso ena ea katleho, bahlahisi ba bone nako ea bohlokoa ea ho boloka nako ea 25% le ho fokotsa litšila tsa thepa ka 30% ha ho bapisoa le mekhoa ea setso, ho latela tlaleho ea Mokhatlo oa Automotive Technology.Lipalopalo tsena tse tlamang li toboketsa ts'itiso ea ho bopa ente ea polasetiki.Ha se feela hore e ntlafalitse tlhahiso ea likarolo tse rarahaneng tse bobebe tse kang li-dashboards, bumpers le grilles, empa hape e nolofalelitse baqapi ba likoloi ho fihlela libopeho tse holimo le lintlha tse ka thusang ho ntlafatsa ts'ebetso ea mafura.

Ho bopa ka ente ea polasetiki ke mokhoa oa tlhahiso o kenyang polasetiki e qhibilihisitsoeng ka har'a mokoti oa hlobo.Hang ha e pholisitsoe 'me e tiile, karolo ea polasetiki e ntšoa ka foromong ho etsa sehlahisoa sa ho qetela se nepahetseng le se tšoarellang.Ts'ebetso ena e na le melemo e mengata ho feta mekhoa e tloaelehileng ea tlhahiso.

Pele ho tsohle, ho bopa ente ea polasetiki ho etsa hore ho be bonolo ho hlahisa likarolo tse rarahaneng.Ka ho sebelisa software e thusoang ke komporo (CAD), baqapi ba likoloi ba ka etsa mefuta ea 3D ea likarolo tse lakatsehang.Joale mehlala ena e fetoloa liforomo, ho tiisa hore karolo e ’ngoe le e ’ngoe e hlahisoang e lula e nepahetse ’me e tsitsitse.

Ho feta moo, tšebeliso eamochini oa ente ea polasetiki ea likoloie nolofalletsa likarolo tse bobebe ntle le ho senya matla le ho tšoarella.Sena se ntlafatsa bokhoni ba mafura, kaha likoloi tse bobebe li hloka matla a fokolang hore li tsamaee.Ho feta moo, mofuta o bobebe oa likarolo tsena tse bōpiloeng o kenya letsoho ts'ebetsong ea kakaretso ea koloi, ho kenyelletsa le ho ts'oaroa ho ntlafalitsoeng le sebaka se khuts'oane sa ho emisa.

Molemo o mong oa bohlokoa oa ho bopa ente ea polasetiki ha ho etsoa likoloi ke bokhoni ba eona ba ho fokotsa litšila tsa thepa.Ho fapana le mekhoa ea setso, eo hangata e kenyelletsang ho seha le ho bōptjoa ho feteletseng ha thepa, ho etsa ente ea polasetiki ho tiisa hore litšila lia fokotseha.Ho feta moo, bokhoni ba ho sebelisa polasetiki e setseng ho tsoa mefuteng e fetileng e boetse e totobatsa mokhoa o tsitsitseng oa ts'ebetso.

Ka ho sebelisa mochini oa ente ea polasetiki, baetsi ba likoloi ba fihla bophahamong bo bocha ba boqapi, bokhoni le botsitso.Mokhoa ona o mocha oa tlhahiso ha oa fetola feela tsela eo likarolo tsa koloi li hlahisoang ka eona, empa hape o file baqapi bolokolohi ba ho hlahloba libopeho le lintlha tse ncha.Phello ke likoloi tse bonahalang tse ipiletsang ho bareki ha li ntse li kenya letsoho bokamosong bo botala.

Qetellong, ho bopa ente ea polasetiki ho fetotse indasteri ea likoloi.Bokhoni ba eona ba ho theha likarolo tse rarahaneng, tse bobebe tse nang le sebopeho se ikhethang le lintlha tse qaqileng li tsamaisitse indasteri pele.Mokhoa ona ha o felle feela ka ho boloka litšenyehelo tse kholo le ho fokotsa litšila tsa thepa, empa hape o thusa ho ntlafatsa ts'ebetso ea mafura le ts'ebetso ea koloi ka kakaretso.Ka ho bopa ente ea polasetiki, baetsi ba likoloi ba ka tsoela pele ho sutumelletsa meeli ea boqapi ho theha likoloi tse sa fihlelleng litlhoko tsa bareki feela empa hape li kenya letsoho bokamosong bo tsitsitseng.

Ente Molding ho Consumer Electronics: Ho Fetola Indasteri

Lisebelisoa tsa elektronike tsa bareki li fetohile karolo ea bohlokoa ea bophelo ba rona, ka li-smartphone, li-laptops le lisebelisoa tsa lapeng li bapala karolo ea bohlokoa ho ntlafatsa bophelo ba rona ba letsatsi le letsatsi.Ka morao ho ts'ebetso, mokhoa o tsotehang oa tlhahiso o bitsoang polasetiki ente molding o phethile karolo e kholo ho fetoleng boemo ba lisebelisoa tsa elektronike tsa bareki, ho nolofalletsa tlhahiso e kholo ea likarolo tse rarahaneng le ho khanna mekhoa e mecha indastering ena e ntseng e hōla.

Ho bopa ka ente ea polasetiki ho fetotse mokhoa oa tlhahiso ea lisebelisoa tsa elektroniki tsa bareki, ho lumella bahlahisi ho etsa meralo e rarahaneng le e nepahetseng eo pele e neng e sa fihlellehe.Sebaka se seng moo ho etsa ente ea polasetiki ho bileng le tšusumetso e kholo ke ea ho bopa lipolasetiki tsa motlakase.Ts'ebetso ena e kenyelletsa ho kenya polasetiki e qhibilihisitsoeng ka har'a liforomo tse tloaelehileng ho etsa likarolo tsa polasetiki tse se nang moeli le tse tšoarellang bakeng sa lisebelisoa tsa motlakase.

Ka lebaka la ts'ebetso ena ea pono e hole, bahlahisi ba fihletse chelete e ngata ea ho boloka ho fihla ho 35% ka litšenyehelo tsa tlhahiso (mohloli: Electronic Manufacturers Association).Ka ho nolofatsa ts'ebetso ea tlhahiso le ho felisa tlhoko ea likarolo tse ngata le likopano, ho bopa ente ea polasetiki ha ho fokotse nako ea tlhahiso feela, empa hape ho eketsa katleho ea kakaretso ea ts'ebetso ea tlhahiso.Ka lebaka leo, lik'hamphani tse indastering ea lisebelisoa tsa elektroniki tsa bareki li fumana phaello e potlakileng ea lihlahisoa le phaello e ntlafalitsoeng.

Khamphani ea rona eOEM / ODMmorekisi oa moetsi ea sebetsanang le hlobo ea ente ea polasetiki bakeng sa lisebelisoa tsa elektroniki tsa bareki.Ka hore hlobo ea rona e romelloe linaheng tse fetang 20, re fumane boiphihlelo bo batsi ba ho fihlela litlhoko tse ikhethang tsa limmaraka tse fapaneng.Re motlotlo ka moralo oa rona oa sebopeho le bokhoni ba ho etsa, ho netefatsa hore bareki ba rona ba fumana liforomo tsa boleng bo holimo le tse tšepahalang.

Ho lisebelisoa tsa elektronike tsa bareki, aesthetics le moralo li phetha karolo ea bohlokoa.Plastiki ke thepa e bonolo haholo e ka kopanyang mesebetsi e mecha le meralo ea motho ka mong.Bokhoni ba ho etsa liteko ka lisebelisoa tse fapaneng tse kang polycarbonate (PC) ho bula tsela bakeng sa lisebelisoa tsa elektroniki tse matla le tse bohehang.Molding ea ente ea PC ke mofuta o ka tlase oa ente ea polasetiki e ka hlahisang likarolo tse nang le thepa e ntle ea mochini, ho hanyetsa mocheso o phahameng le ho hlaka ho hoholo ha mahlo.Sena se phahamisitse boemo bo holimo ho lisebelisoa tsa elektronike tsa bareki, ho fa basebelisi lisebelisoa tse sa sebetseng hantle feela, empa hape li boreleli ebile li rarahane ka moralo.

Ho bopa ente ea polasetikie kentse lisebelisoa tsa elektronike tsa bareki sebakeng sa menyetla e sa feleng.Ho hloka seams le katleho ea ts'ebetso ena ea tlhahiso e lumella bahlahisi ho fihlela litlhoko tse lulang li fetoha tsa bareki ba tech-savvy.Ho tloha ho li-smartphones tse nang le li-bezel-low displays ho ea ho li-laptops tse nang le mefuta e menyenyane haholo, ho etsa ente ea polasetiki ho 'nile ha e-ba ka pele-pele ho theheng lisebelisoa tse seng tse tsoetseng pele tsa theknoloji feela empa li shebahala ka tsela e hlollang.

Qetellong, ho bopa ente ea polasetiki ho fetotse indasteri ea lisebelisoa tsa elektroniki tsa bareki.Ka bokhoni ba ho hlahisa likarolo tse rarahaneng ka potlako le ka theko e tlaase, bahlahisi ba amohetse mokhoa ona oa ho tlisa lisebelisoa tsa morao-rao 'marakeng.Ka ho kopanya meralo e ncha le lisebelisoa tse matla joalo ka polycarbonate, ho bopa ente ea polasetiki ho khonne ho theha lisebelisoa tsa elektronike tse khahlang le tse khahlang tsa bareki.Ka lebaka la ts'ebetso ena e sebetsang hantle ea tlhahiso, bokamoso ba lisebelisoa tsa elektroniki tsa bareki bo shebahala bo khanya ho feta leha e le neng pele, ka mefuta e mengata ea lisebelisoa tse ncha le tse khahlang tse lebelletsoeng ho thabisa batho ba chesehelang theknoloji lefatšeng ka bophara.

Ho Bopa ka Ente ea Plastiki Lefapheng la Liphutheloana

Indasteri ea liphutheloana, e tsebahalang ka boqapi le boqapi ba eona, e bile le ts'ebetso e ncha ka ho fihla ha mochini oa ente ea polasetiki.Ka ho sebelisa theknoloji ena ea katleho, bahlahisi ba ka fokotsa litšenyehelo tsa bona haholo ka 40% (mohloli: Packaging Professionals Association).

Ho bopa ka ente ea polasetiki ho fetotse tsela eo litharollo tsa liphutheloana li entsoeng ka eona, haholo-holo ka hlobo ea preform, hlobo ea PET preform, hlobo ea polasetiki ea li-cap le li-preform blow molding.Mefuta ena e bohlokoa bakeng sa tlhahiso ea likarolo tse fapaneng tsa ho paka ho kenyelletsa libotlolo, lijana le ho koaloa.

Ho feto-fetoha ha ente ea polasetiki ho ka hlahisa litharollo tse khahlehang tsa liphutheloana tse sa netefatseng feela polokeho ea sehlahisoa le bophelo bo bolelele, empa hape li hohela bareki ka likarolo tsa moralo tse khahlang mahlo.Ka ho sebelisa hlobo ea preform, bahlahisi ba khona ho etsa libotlolo le lijana tse se nang moeli le tse ntle.Mefuta ea PET preform ka ho khetheha e hlahisa litharollo tsa ho paka tse pepeneneng le tse tšoarellang tse sebelisoang haholo indastering ea lino le lijo.

Ho feta moo, libotlolo tsa polasetiki li ka etsa hore ho koaloe ho sireletsehileng le ho sa lutle bakeng sa libotlolo le lijana.Likoahelo tsena ha li sireletse litaba tsa sephutheloana feela, empa hape li fana ka boiketlo le boiketlo ba tšebeliso bakeng sa bareki.Ho nepahala le bokhoni ba ho bopa ente ea polasetiki ho netefatsa hore sekoahelo se seng le se seng se hlahisoang ke sa boleng bo tsitsitseng, se hlahisang tharollo e tšepahalang ea ho paka.

Ho feta moo, ho etsa preform blow molding e se e le mokhoa o tsebahalang indastering ea ho paka.Mokhoa ona o kenyelletsa ho kenya lintho tsa polasetiki tse futhumetseng ka har'a hlobo, ebe e atolosoa ka moea o hatelitsoeng ho etsa karolo e sekoti ea ho paka.Preform blow molding e fana ka sebopeho se ikhethileng, se nolofalletsang bahlahisi ho etsa libopeho le boholo bo ikhethang bakeng sa tharollo ea bona ea liphutheloana.Sena ha se ntlafatse feela botle ba sehlahisoa, empa hape se ntlafatsa phihlelo ea bareki.E bobebe empa e tšoarella, litharollo tsena tsa liphutheloana tse bopehileng li fana ka boiketlo le ho nkeha habonolo bakeng sa bareki ha li ntse li fokotsa litšenyehelo tsa thomello bakeng sa bahlahisi.

Ho bopa ente ea polasetiki ho bula tsela bakeng sa litharollo tse tšoarellang tsa liphutheloana tse sebelisang thepa e nchafalitsoeng.Indasteri e ntse e tsoela pele ho fetohela ho lisebelisoa tse baballang tikoloho joalo ka bioplastics, tse nkiloeng mehloling e nchafalitsoeng mme li ka sebelisoa hape habonolo.Ka ho sebelisa mochini oa ente ea polasetiki, bahlahisi ba khona ho fokotsa tšusumetso ea bona ea tikoloho ha ba ntse ba fana ka litharollo tse ncha tsa ho paka.

Likhamphani tse indastering ea ho paka li hlokometse melemo e meholo ea ho bopa ente ea polasetiki 'me li e kenyelletse lits'ebetsong tsa tsona tsa tlhahiso.Likhamphani tsena li sebelisa hlobo ea preform, hlobo ea PET preform, hlobo ea polasetiki, le mahlale a preform blow molding ho hlahisa litharollo tsa ho paka tsa boleng bo holimo, tse theko e tlaase le tse tšoarellang.

Ka kakaretso, ho bopa ente ea polasetiki ho tlisitse liphetoho tse kholo indastering ea ho paka.Ka ho sebelisa hlobo ea preform, hlobo ea PET preform, hlobo ea polasetiki, le mahlale a preform blow molding, bahlahisi ba khonne ho hlahisa litharollo tse tlamang tsa ho paka tse netefatsang polokeho ea sehlahisoa, bophelo bo bolelele le khotsofalo ea bareki.Ho feta moo, ho etsa ente ea polasetiki ho thusa ho nts'etsapele litharollo tse tšoarellang tsa ho paka, ho kenya letsoho phokotsong ea phello ea indasteri ea tikoloho.Ka ho feto-fetoha ha eona le ho atleha ha eona, ho bopa ente ea polasetiki e ntse e le matla a susumetsang bokamoso ba indasteri ea ho paka.

Ho bopa ka Ente ea Plastiki ho Tlhokomelo ea Bophelo: Phetoho ea Tšireletseho ea Mokuli le Bophelo bo Botle ho tsa bophelo bo botle

Mekhoa ea tlhahiso e nepahetseng le e ka tšeptjoang e bohlokoa ho netefatsa polokeho ea mokuli le bophelo bo botle ka kakaretso.Sehlahisoa se seng le se seng sa bongaka se sebelisoang ke bafani ba tsa bophelo bo botle se tlameha ho fihlela litekanyetso tse thata tsa boleng, ho nepahala le ho hloka matla.E le ho finyella lipakane tsena, ha ho pelaelo hore ho kenngoa ha mochini oa ente ea polasetiki e bile phetoho.Ts'ebetso ena ea tlhahiso e fetotse indasteri ea tlhokomelo ea bophelo ka ho lumella bahlahisi ho fana ka lihlahisoa tsa bongaka tse nepahetseng, tsa boleng bo holimo.Bafani ba tsa bophelo bo botle ba bone lintlafatso tse makatsang mabapi le ho nepahala ha tlhahiso ka lebaka la ente ea polasetiki.Ho latela Medical Manufacturing Association, ts'ebetso ena e bakile phokotso e kholo ea 50% ea bofokoli ba sehlahisoa(mohloli: Medical Manufacturing Association) .

Tiisetso ena ea boleng bo holimo e bohlokoa ha ho etsoa lisebelisoa tsa bohlokoa tsa bongaka tse kang li-syringe, li-catheters le lisebelisoa tsa ho buoa.Ka ho fokotsa bofokoli, bakuli le litsebi tsa bophelo bo botle ba ka itšetleha ka lihlahisoa tsena ka kholiseho ea ho tseba hore ts'ebetso ea bona le polokeho ke tsona tse tlang pele bophelong.E 'ngoe ea melemo e ka sehloohong ea ho bopa ente ea polasetiki ke bokhoni ba ho etsa bonnete ba hore lihlahisoa tsa bongaka li hloekile.Sebakeng sa tlhokomelo ea bophelo bo botle, kotsi ea tšoaetso ke taba e kholo.Leha ho le joalo, ka ho bōptjoa ha ente ea polasetiki, bahlahisi ba ka hlahisa lisebelisoa tsa bongaka tse sa hloekang ka ho toba ho tloha hlobo.Sena se felisa tlhokahalo ea ts'ebetso e eketsehileng ea sterilization, ho fokotsa monyetla oa ho silafatsa le ho ntlafatsa tlhokomelo ea bakuli.Ka ho fokotsa kotsi ea tšoaetso, litsi tsa tlhokomelo ea bophelo li ka fana ka tikoloho e sireletsehileng bakeng sa bakuli, qetellong li khothalletsa ho hlaphoheloa le boiketlo ba bona.

Ho feta moo, ho bopa ente ea polasetiki ho etsa hore ho be le tlhahiso e nepahetseng le e sebetsang ea lisebelisoa tse rarahaneng tsa bongaka.Ho feto-fetoha ha mokhoa ona oa tlhahiso ho etsa hore ho be le meralo e rarahaneng, ho etsa bonnete ba hore lihlahisoa tsa bongaka li kopana ka mokhoa o tsitsitseng le ho sebetsa ka mokhoa o se nang sekoli.Hore na ke lisebelisoa tse rarahaneng tsa ho buoa kapa li-syringe tse lekantsoeng hantle, mochini oa ente ea polasetiki o thusa bahlahisi ho fihlela litlhoko tse batloang ke indasteri ea tlhokomelo ea bophelo.

Ts'ebetso ena e nepahetseng le e sebetsang hantle ha e thuse bakuli feela, e boetse e thusa ho boloka litšenyehelo bakeng sa bafani ba tlhokomelo ea bophelo le ho etsa hore tlhokomelo ea boleng e fihlellehe ho baahi ba bangata.Tšusumetso ea ente ea polasetiki molemong oa tlhokomelo ea bophelo e fetela hole le ts'ebetso ea tlhahiso ka boeona.Ka ho sebelisa theknoloji ena e tsoetseng pele, indasteri ea tlhokomelo ea bophelo lefatšeng ka bophara e phahamisa maemo a holimo.Ha ho nepahala le ho tšepahala ho fetoha ntho e tloaelehileng, boleng ba kakaretso ba lihlahisoa tsa bongaka bo ntlafala, bo lebisang liphellong tse ntle tsa mokuli.Ho tloha ho fokotsa kotsi ea tšoaetso ho ea ho fokotsa bofokoli ba lihlahisoa, ho bopa ente ea polasetiki ho phetha karolo ea bohlokoa ho pholosa bophelo le ho ntlafatsa maemo a kakaretso a tlhokomelo ea bakuli.Ha indasteri ea tlhokomelo ea bophelo e ntse e tsoela pele ho fetoha, ho joalo le ka tlhokahalo ea lihlahisoa tsa bongaka tse nepahetseng, tse tšepahalang.Ho bopa ente ea polasetiki ho sebetsana le litlhoko tsena ka kotloloho, ho fa bahlahisi lisebelisoa tseo ba li hlokang ho fana ka boleng bo ikhethang le botsoali.Matla a phetoho a ts'ebetso ena ea tlhahiso a lumella bafani ba tlhokomelo ea bophelo ho tsepamisa maikutlo ho seo e leng sa bohlokoa haholo: bophelo bo botle le boiketlo ba bakuli ba bona.

Qetellong, ho bopa ente ea polasetiki ho fetohile phetoho ea papali tlhahisong ea tlhokomelo ea bophelo.E thusa ho hlahisa lihlahisoa tsa bongaka tsa boleng bo holimo, tse nepahetseng le tse nyopa, ho fokotsa kotsi ea tšoaetso le ho matlafatsa tlhokomelo ea bakuli.Ka ts'ebetso ena ea phetoho, indasteri ea tlhokomelo ea bophelo lefats'e ka bophara e pholosa bophelo le ho phahamisa boemo ba bokhabane.Ka tlhoko e ntseng e hola ea liphetho tse betere tsa mokuli, ha ho pelaelo hore ho bopa ente ea polasetiki ho tla bapala karolo e kholo ho bopeng bokamoso ba tlhahiso ea tlhokomelo ea bophelo.

Qetello

Ho bopa ente ea polasetiki ho kentse nako ea menyetla e se nang moeli le boqapi ba phetoho ho liindasteri tsa B-End.Ka ho bonts'a mehlala ea lefats'e la 'nete le ho e tšehetsa ka lintlha tse matla, re bone phello e makatsang ea mokhoa ona tlhahisong ea likoloi, lisebelisoa tsa elektroniki tsa bareki, indasteri ea ho paka le tlhokomelo ea bophelo bo botle.Ho boloka litšenyehelo, meralo e ntlafalitsoeng, le ntlafatso e nepahetseng ea tlhahiso e fanoang ke mochini oa ente ea polasetiki li fetotse mafapha ana, a siea letšoao le sa hlakoheng tsoelopeleng le kholong ea tsona.Ha re ntse re amohela menyetla e se nang moeli ea ho bopa ente ea polasetiki, re bona bokamoso bo khanyang bo tletseng bokhoni bo sa feleng ba ho etsa bokhabane le khotsofalo ea bareki.

Kahoo, a re qaleng leetong lena le tsotehang, moo boqapi, bokhoni, le ts'ebetso e tsitsitseng li thulanang ka mokhoa o matla oa ho bopa ente ea polasetiki.Hammoho, re ka theha lefatše leo ho lona boqapi bo sa tsebeng moeli, 'me indasteri e' ngoe le e 'ngoe e atleha ka thuso ea theknoloji ena e makatsang.

Ikutloe u lokolohile hotshoanyaronaneng kapa neng!Re mona ho thusa 'me re ka thabela ho utloa ho tsoa ho uena.

Lintlha tsa Feme

Mefuta e Fetang

Thomello

Tšebeletso e khethehileng ea ho paka bakeng sa hau: Nyeoe ea lehong e nang le filimi

1. Ho netefatsa hantle polokeho ea thepa ea hau, setsebi.

2. Ho tla fanoa ka litšebeletso tse ntle tsa tikoloho, tse loketseng le tse sebetsang hantle tsa ho paka.

LBH

HSLD: E, hangata likarolo tse setseng tsa hlobo ea die casting re na le hlobo e kentsoeng, foreimi ea hlobo, mokokotlo oa fensetere, mokokotlo o tsamaeang, hlooho ea nozzle.U ka hlahloba le ho tsebisa hore na u hloka likarolo life tse setseng.

HSLD: Mould oa rona o entsoe ka DAC.

HSLD: Mokotla oa rona o tsamaeang o entsoe ka FDAC.

HSLD: Ho joalo.

HSLD: Lisebelisoa tse fapaneng li na le ho nepahala ho fapaneng, ka kakaretso pakeng tsa 0.01-0.02mm