E Fetileng Molds Ho etsa le Mahala lihlahisoa moralo

Lits'ebeletso tsa rona tsa ho Enta ka Plastiki

Ho sebelisa CNC Machining ho fana ka liphetho tse phahameng

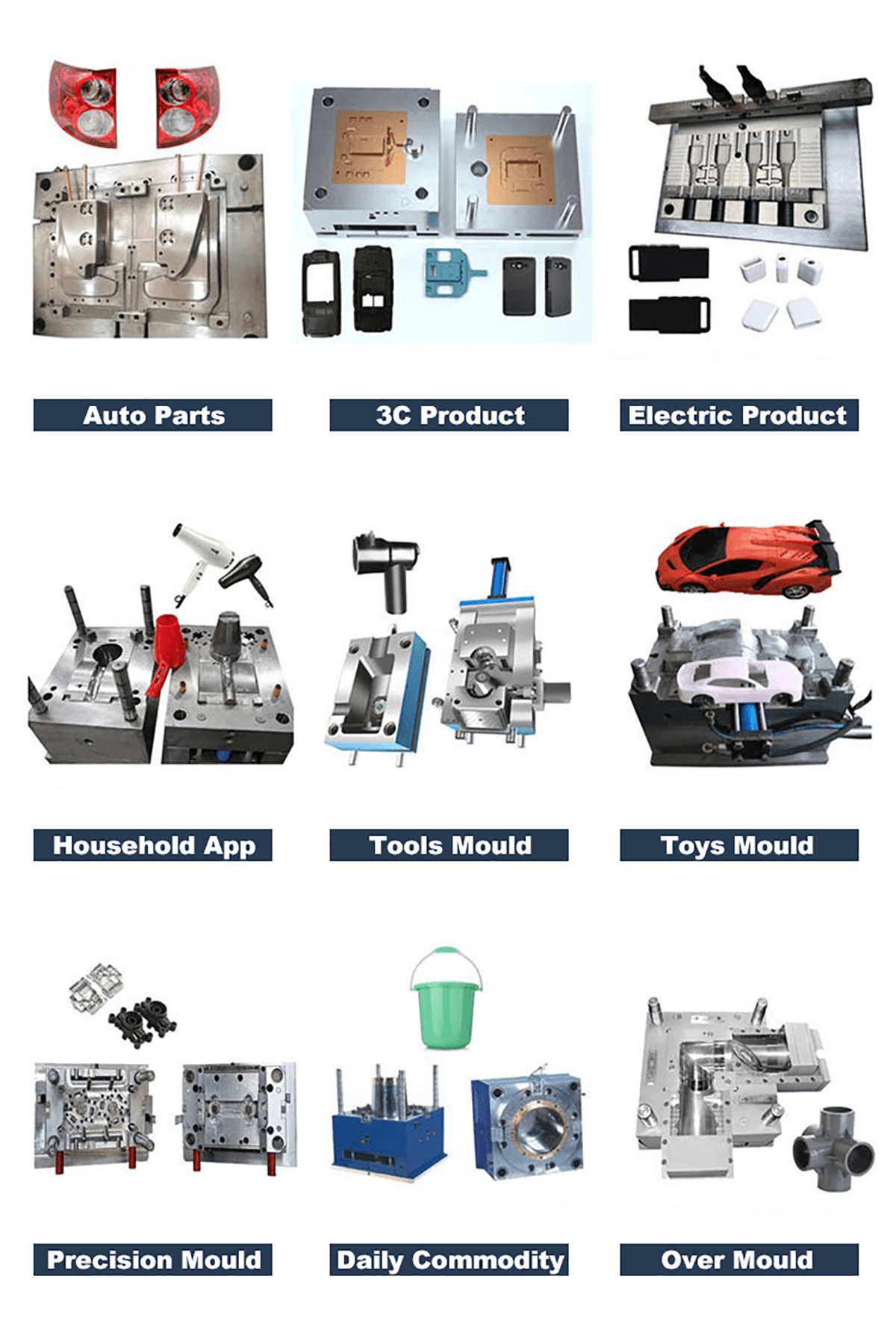

Lefapheng la tlhahiso, mokhoa oa tlhahiso ea hlobo ea ente ea polasetiki e phetha karolo ea bohlokoa.Mefuta ena e bohlokoa haholo tlhahisong ea lihlahisoa tse fapaneng, ho kenyeletsoa lisebelisoa tsa lapeng, lintho tsa ho bapala, lisebelisoa tsa elektroniki tsa 3C, likarolo tsa koloi le litlhoko tsa letsatsi le letsatsi, joalo-joalo. Khamphaning ea rona, re motlotlo haholo ka ho fana ka lits'ebeletso tsa boemo ba pele ba ho bopa ente ea polasetiki.Ka boiphihlelo ba rona ba nakong e fetileng le boitseanape ba rona, re ithutile tsebo ea ho etsa liforomo ho ea maemong a holimo ka ho fetisisa a indasteri.Ntle le moo, re sebelisa machining a CNC, mokhoa o mocha oa tlhahiso o netefatsang tlhahiso e potlakileng le e nepahetseng ea likarolo tse entsoeng ka ente.

Mabapi le rona:

Khampani ea rona e na le tlaleho e tsotehang tšimong ea tlhahiso ea hlobo.Ka lilemo tsa boiphihlelo ba indasteri, re atlehile ho sebetsana le mefuta e fapaneng ea hlobo ho fihlela litlhoko tsa liindasteri tse fapaneng.Ho tloha ho lisebelisoa tsa ntlo ho isa ho lisebelisoa tsa elektroniki tsa maemo a holimo, re hlahisa mefuta e mengata ea lihlahisoa ho netefatsa khotsofalo ea bareki nako le nako.Boitlamo ba rona ba bokhabane le ho ela hloko lintlha li thehile seriti sa rona re le morekisi ea tšepahalang oa ente ea polasetiki.

Ithute ka hlobo ea ente:

Ho etsa ente ea polasetiki ke mokhoa o sebelisoang haholo oa tlhahiso o kenyelletsang ho kenya polasetiki e qhibilihisitsoeng ka har'a hlobo e tloaelehileng.Ts'ebetso ena e ka theha libopeho le libopeho tse rarahaneng tseo ho seng joalo ho neng ho tla ba thata ho li fihlela.Thepa ea polasetiki e tiisa ka hare ho hlobo, e nka sebōpeho le moralo oa sekoti sa hlobo.Hang ha e pholile ebile e thatafalitsoe, likarolo tse bōpiloeng lia ntšoa, li loketse ho tsoela pele ho sebetsa kapa ho kopana.

Ente hlobo CNC machining:

Khamphaning ea rona, re entse machining a CNC karolo ea bohlokoa ea ts'ebetso ea rona ea tlhahiso.CNC (Computer Numerical Control) ke mokhoa o sebelisang sistimi ea taolo ea komporo ho sebelisa mochini o nepahetseng.Lefapheng la hlobo ea ente ea polasetiki, machining a CNC a ntlafatsa ts'ebetso le ho nepahala, ho fella ka lihlahisoa tsa boleng bo holimo.

Ho na le melemo e mengata ea ho sebelisa mochini oa CNC tlhahiso ea hlobo ea ente ea polasetiki.Ntlha ea pele, e fokotsa haholo nako ea tlhahiso e hlokahalang bakeng sa hlobo ka 'ngoe.Lisebelisoa tse laoloang ke k'homphieutha li thusa ho etsa mechine e potlakileng, e nepahetseng bakeng sa ho phethoa ka potlako.Linako tse fokotsehileng tsa ho etella pele ke molemo o moholo bakeng sa likhoebo kaha li fetolela ka kotloloho nako e khuts'oane ea tlhahiso le nako e potlakileng ea ho ea 'marakeng.

Taba ea bobeli, machining a CNC a netefatsa ho nepahala ho ikhethang ha ho etsoa hlobo ea ente ea polasetiki.Sistimi ea taolo e ikemetseng e khona ho theha meralo e rarahaneng haholo ka ho nepahala ho fetisisa.Boemo bona ba ho nepahala bo tiisa hore sehlahisoa sa ho qetela se pheta ka botšepehi hlobo e reriloeng, se finyella lintlha le litlhoko tse nepahetseng tsa moreki.

Ntle le moo, machining a CNC a thusa ho pheta-pheta ha ho etsoa hlobo ea ente ea polasetiki.Sistimi ea taolo ea komporo e tiisa hore hlobo e 'ngoe le e 'ngoe e hlahisoang e tšoana hantle le moetso oa pele.Ho lumellana hona ho bohlokoa, haholo ha ho etsoa lihlahisoa ka bongata kapa ho boloka botsitso lipakeng tsa lihlahisoa tse fapaneng.

ha re phethela:

k'hamphani ea rona e motlotlo haholo ka ho fana ka ts'ebeletso e felletseng bakeng sa hlobo ea ente.Re na le rekoto e netefalitsoeng ea ho fana ka liforomo tsa maemo a holimo bakeng sa mafapha a fapaneng a kang lisebelisoa tsa lapeng, lintho tsa ho bapala, lisebelisoa tsa elektroniki tsa 3C, likarolo tsa koloi le litlhoko tsa letsatsi le letsatsi.Tšebeliso ea rona ea mochini oa CNC e ntlafatsa le ho feta bokhoni ba rona ba ho hlahisa hlobo kapele le ka nepo.Ts'ebetso ena e ikhethang ea tlhahiso e netefatsa hore bareki ba rona ba fumana kapele likopi tse phethahetseng tsa likarolo tsa polasetiki tseo ba li hlokang.Hore na o hloka liforomo tse bonolo kapa meralo e rarahaneng haholo, re ka fana ka tharollo e potlakileng le e khotsofatsang litlhoko tsa hau tsa ente ea polasetiki.

Lintlha tsa Sehlahisoa

| Sebaka sa Tšimoloho | China |

| Lebitso la Brand | HSLD/ E etselitsoeng motho |

| Mokhoa oa ho Shaping | Fans Plastic Ente Mold |

| Thepa | CNC, Mochini o Sehang oa EDM, Mechini ea polasetiki, joalo-joalo |

| Boitsebiso ba Sehlahisoa | Tšepe: AP20/718/738/NAK80/S136 Plastiki: ABS/PP/PS/PE/PVC/PA6/PA66/POM |

| Bophelo ba Hlobo | 300000 ~ 500000 Shots |

| Semathi | Semathi se Chesang kapa Semathi se Cold |

| Mofuta oa heke | Ntlheng / Pin point/Sub/Side Heke |

| Phekolo ea bokaholimo | Matte, e bentšitsoeng, seipone se bentšitsoeng, sebopeho, pente, joalo-joalo. |

| Mold Cavity | Mokoti o le Mong kapa o Angata |

| Mamello | 0.01mm -0.02mm |

| Mochini oa Ente | 80T-1200T |

| Mamello | ± 0.01mm |

| Mohlala oa mahala | fumaneha |

| Molemo | tharollo e le 'ngoe ea ho emisa / moralo oa mahala |

| Sebaka sa kopo | Lihlahisoa tsa elektroniki, lihlahisoa tsa botle, lihlahisoa tsa bongaka, Lihlahisoa tse sebelisoang lapeng, Lihlahisoa tsa Auto, jj |

Lintlha tsa Feme

Mefuta e Fetang

Thomello

Tšebeletso e khethehileng ea ho paka bakeng sa hau: Nyeoe ea lehong e nang le filimi

1. Ho netefatsa hantle polokeho ea thepa ea hau, setsebi.

2. Ho tla fanoa ka litšebeletso tse ntle tsa tikoloho, tse loketseng le tse sebetsang hantle tsa ho paka.

LBH

HSLD: E, hangata likarolo tse setseng tsa hlobo ea die casting re na le hlobo e kentsoeng, foreimi ea hlobo, mokokotlo oa fensetere, mokokotlo o tsamaeang, hlooho ea nozzle.U ka hlahloba le ho tsebisa hore na u hloka likarolo life tse setseng.

HSLD: Mould oa rona o entsoe ka DAC.

HSLD: Mokotla oa rona o tsamaeang o entsoe ka FDAC.

HSLD: Ho joalo.

HSLD: Lisebelisoa tse fapaneng li na le ho nepahala ho fapaneng, ka kakaretso pakeng tsa 0.01-0.02mm